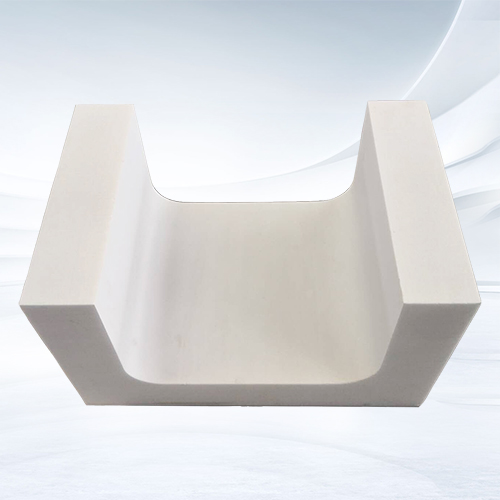

Alpha Beta Alumina block for glass fusing kiln stout brick, lip brick, gate brick

Fused corundum bricks are made by melting alumina in an electric arc furnace and casting them into a model of a specified specific shape, annealing and heat preservation, and then processing diamond abrasive tools to obtain the desired product.

This product is divided into 3 types according to the different crystal forms and quantity of alumina. The first type is α-Al2O3 as the main crystal phase, called α corundum brick; the second type is α-Al2O3 and β-Al2O3 The main crystal phase, the content is basically 1:1, the α phase content is slightly higher, called α, β corundum brick; the third type is mainly β-Al2O3 crystal phase, called β corundum brick.

Alpha Beta Alumina block for glass fusing kiln stout brick, lip brick, gate brick

The fused cast corundum brick has good high temperature volume stability and corrosion resistance.

The structure of α-Al2O3 fused cast bricks is dense and has certain resistance to glass melt erosion and erosion resistance.

β-Al2O3 fused cast bricks contain almost no glass phase, basically no shrinkage cavity, good thermal shock resistance, and high temperature resistance to alkali vapor stability.

α-β Al2O3 fused cast bricks have the characteristics of α-Al2O3 and β-Al2O3 fused cast bricks. The main crystal phases are directly combined, and the composition contains only a small amount of glass phase. The crystal structure is compact, the porosity is low, the high temperature wear resistance is good, the mechanical strength is high, and it has good high temperature resistance to alkali vapor stability.

Wechat Us

Wechat Us