Fused cast alumina block introduction

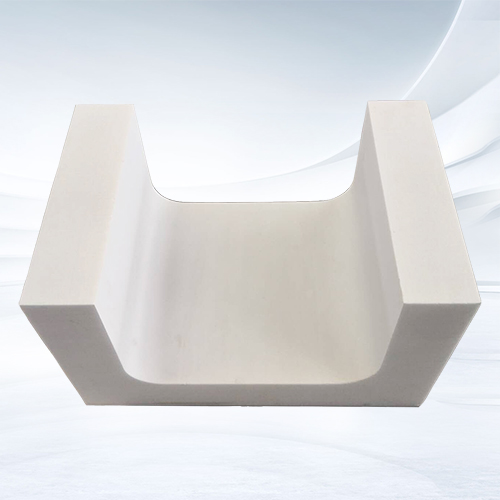

Fused cast alumina block is produced by special electric melting furnace which in the temperature is nearlly 2000°C, the major raw materials is high purity alumina oxide. Fused cast Alumina Block is formed by the compact structure of alpha alumina and beta alumina crystals in a most ideal proportion which is approximately 50% and 50% respectively,where intertwined crystals of both materials result in a very dense structure and no contamination to glass metal. It is the desired refractory materials for channels, spouts and working ends of floating glass furnace.

Fused cast alumina block accroding the alpha and beta crystals diffenence, include three type whcih name fused cast alumian alpha block, fused cast alumina beta block, fused cast alumina alpha-bate block.

Fused cast alumina characters Specifications and applications

* Below 1350 ℃, fused cast block has excellent corrosion resistance and great performance against contamination to molten glass, so it is very suitable as glass tank paving blocks and fore-hearth channel blocks.

* When in contact with molten glass, it barely produces any blistering or stones. fused cast alumina blocks widely used in working end of tank, tannk bottom,feeder channels, superstructures, throat etc.

Features

1. High refractoriness

2. Better resistance to glass liquid

3. Excellent thermal stability

Physical properties and chemical composition

Item | HT-M (α-βAlumina) | |

Chemical Composition % | Al2O3 | 94 |

Na2O | 4 | |

SiO2 | 1 | |

CaO | 0.1 | |

Fe2O3 | 0.25 | |

True density g/cm3 | ≥3.52 | |

Cold Crushing Strength Mpa | ≥200 | |

Refractoriness Under Load °C | 1700 | |

Bulk Density (g/cm3) | PT(RN) | ≥3.2 |

WS( VF) | ≥3.35 | |

Crystallographic analysis % | α-Al2O3 | 44 |

β-Al2O3 | 55 | |

Glass Phase | 1 | |

Wechat Us

Wechat Us