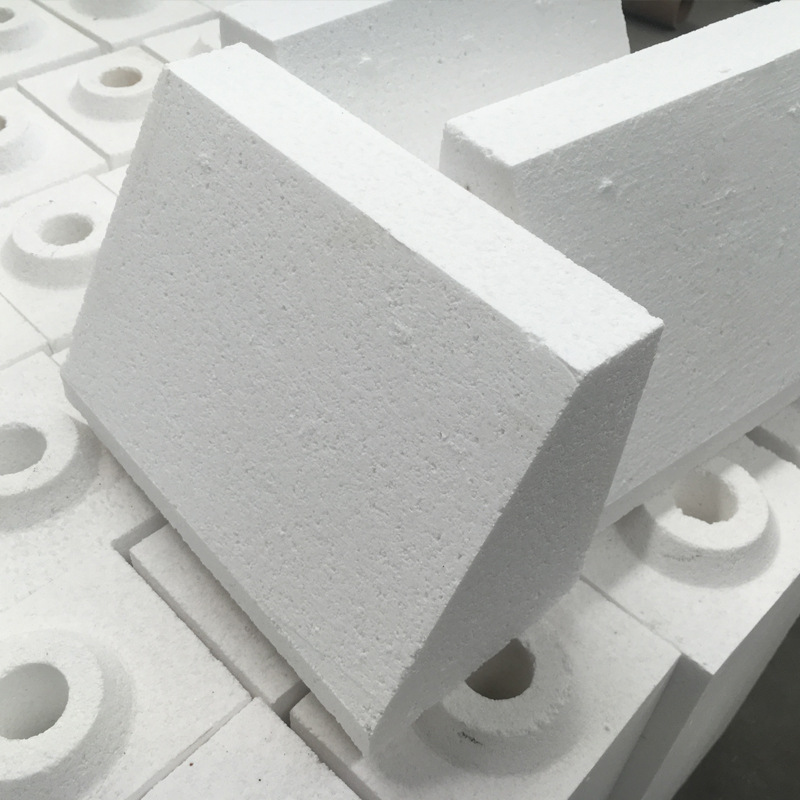

Alumina Bubble Bricks

Alumina bubble bricks are made of alumina bubble balls and alumina powder as the main raw materials, combined with other binders, and fired at a high temperature of 1750 degrees. It is a kind of ultra-high temperature resistance and energy-saving insulation refractory material. Alumina bubble bricks not only have light density which can optimize the structure to reduce the weight of the furnace body, but also have low thermal conductivity, which has a good thermal insulation effect. It can be directly built on the lining of the high-temperature furnace that is in contact with the flame, and can also be used to manufacture high-temperature furnace tubes, trays, protective covers, etc. The performance of alumina bubble bricks is generally determined by the chemical composition. Except for the production process ,some factors such as particle ratio, molding pressure and firing temperature are also very important to the quality of the bricks.

As a professional alumina bubble bricks manufacturer, we have exported different typess alumina bubble refractory bricks to more than 30 countries. Please kindly read the following more information and make Inquiry

Scope of application:

Alumina bubble bricks are mainly used as the lining of high-temperature industrial kilns below 1800°C, such as petroleum, chemical, electronics, ceramics, refractory materials and other industries. It plays a pivotal role in various industries.

Advantage:

l High tempreture resistance more than 1750°C

l Good thermal stability at high temperature and long service life

l Optimize the furnace structure and reduce the weight of the furnace body

l Save the quantity of other insulation refractory material used in the furnace

l Save energy consumption and improve the thermal efficiency

Technical Data:

| Items | Ultra Purity Bubble Alumina Brick | Bubble Alumina Brick | ||

| HAB-99 | SAB-99 | SAB-90 | SAB-85 | |

| Max Service temperature ℃ | 1800 | 1800 | 1800 | 1750 |

| Al2O3 % | ≥99.3 | ≥99 | ≥90 | ≥85 |

| SiO2 % | ≤0.15 | ≤ 0.3 | ≤ 9 | ≤ 14 |

| Fe2O3 % | ≤0.1 | ≤ 0.2 | ≤ 0.2 | ≤ 0.2 |

Bulk density (g/cm3) | 1.5~1.8 | 1.5~1.8 | 1.4~1.9 | 1.4~1.9 |

| Cold compression strength (Mpa) | ≥12 | ≥15 | ≥18 | ≥18 |

| Refractoriness under load (0.1Mpa,0.6%) | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

| Reheating linear change (1600℃x8h) % | -0.25 | -0.25 | ±0.2 | ±0.3 |

Room temp to 1300℃ Thermal expansion coefficient | 8.6 | 8.6 | 8.0 | 7.8 |

Thermal Conductivity W/(m.k) 800℃ | 0.75 | 0.75 | 0.6 | 0.55 |

Wechat Us

Wechat Us