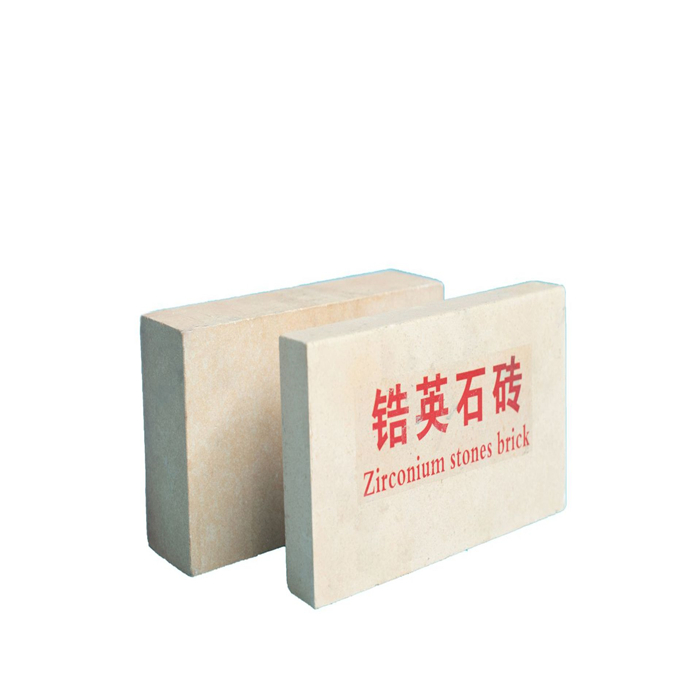

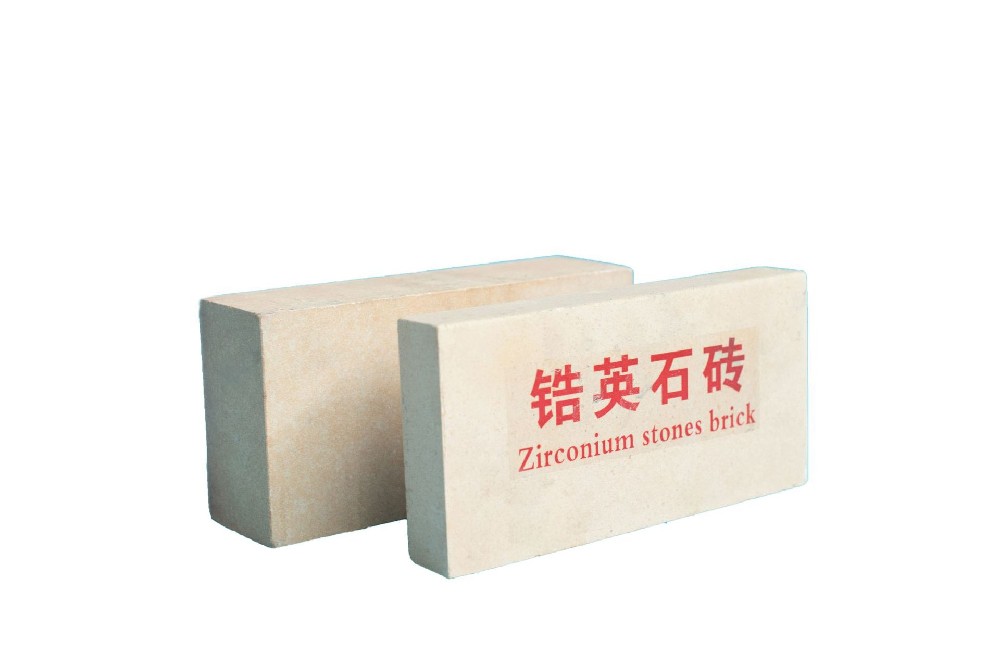

Zircon brick:

Zircon refractory brick is made of natural zircon sand (ZrSiO2) as raw material. The zircon silicate brick is fired in 1600℃ furnace with the zircon content more than 65%. The Zircon bricks have compact crystal structure, high density and high mechanical strength. Since it has good thermal shock stability, low re-fire shrinkage and high temperature creep, and has extremely high chemical stability and resistance to alkaline media, it is widely used in glass industry.

As a professional zirconia bricks manufacturer, we have exported different zircon refractory bricks to more than 30 countries. Please kindly read the following more information and make Inquiry

Scope of application:

l Zircon Silicate bricks is widely used in Lining of alkali-free or low-alkali glass, sodium-calcium glass, boron-silicate glass, ceramic glass,lead glass, and other technical glass melting furnace.

Advantage:

l Good slag resistance

l Low thermal expansion rate

l Thermal conductivity decreases with increasing temperature

l High load softening temperature

l High abrasion resistance

l Good thermal shock resistance

l Long using life

Technical Data:

Item | Zircon Bricks | |||

ZS65JA | ZS65JB | ZS60 | ||

Chemical Composition | ZrO2% ≧ | 65 | 65 | 60 |

SiO2% ≦ | 33 | 33 | 36 | |

Fe2O3% ≦ | 0.3 | 0.3 | 0.5 | |

Bulk Density(g/cm2)≧ | 3.85 | 3.75 | 3.60 | |

Apparent Porosity(%) ≦ | 16 | 18 | 20 | |

Cold Crushing Strength(MPa)≧ | 100 | 100 | 100 | |

0.2MPa Load Softening Start Temperature≧ | 1700 | 1700 | 1500 | |

Thermal Shock Stability | excellent | excellent | / | |

We can also produce the zircon bricks according to the customer's datasheet requirements

Wechat Us

Wechat Us