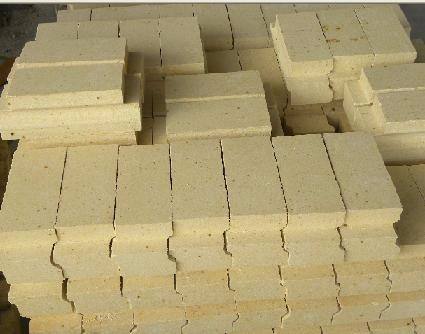

Silica brick for coke oven

Property:

2. High thermal conductivity

3. Good thermal shock resistance.

4. High temperature volume stability.

Silica bricks for hot-blast stove

Property of Silica bricks for hot-blast stove

1. Under the condition of long-term high temperature and load, the volume is stable, the high temperature creep rate is low, and one or even two BF service can be used continuously.

2.600℃ above have good thermal shock resistance. Adapt to the variability of temperature of hot-blast stove, keep the bricks and masonry intact;

3. The resistance to chemical erosion is better than that of clay bricks and general high alumina bricks. The alkaline substance in the gas and soot is only limited to the surface forming a glass phase, and does not peel off the silicon brick.

4. The thermal conductivity of silica bricks is larger than that of clay bricks and high alumina bricks, which facilitates the storage and release of heat in a relatively short time.

Wechat Us

Wechat Us